Today, we presented some pictures of the new bodywork on our Facebook page. The images are rendered 3D CAD images. To see more pictures – Like us on Facebook!

Category Archives: Manufacturing

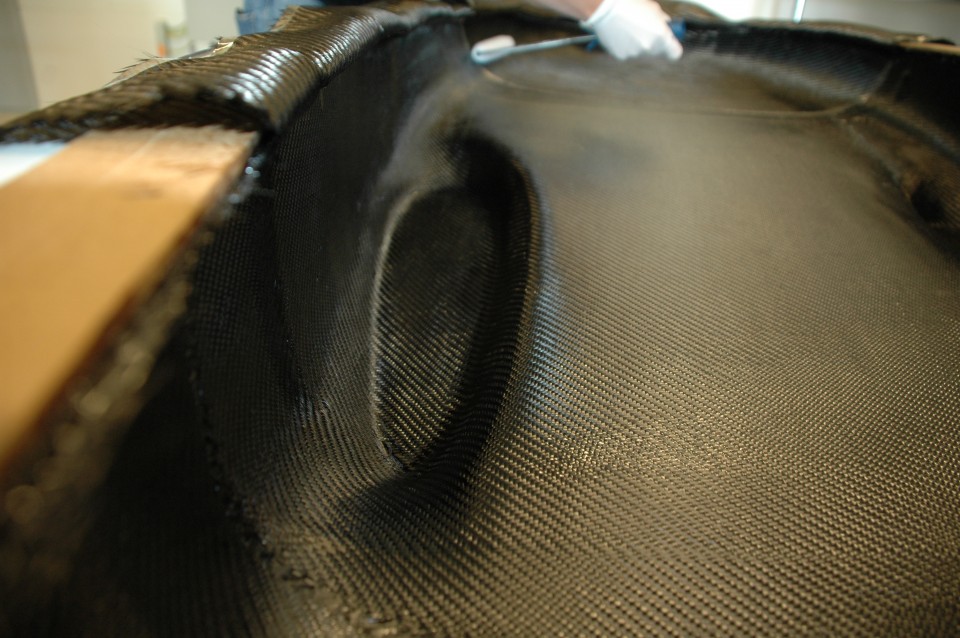

Carbon fibre casting of the new body

As the molds are finished we’ve started to manufacture the new bodywork. This is being done by carbon fibre casting. Carbon fibre is an extremely strong and light material, which in recent years has become the obvious choice when light weight and strength is being prioritized. For example, Formula 1 car bodies are built up of carbon fibre.

The carbon fibre mat is very flexible, making it optimal even for difficult geometries. The carbon fibre mat is supplemented with epoxy as binder, which then is being vacuum bagged to allow the bodywork to harden.

Have a look at the gallery below to see how it works!

Remember to follow us on Facebook, where we give you updates more often!

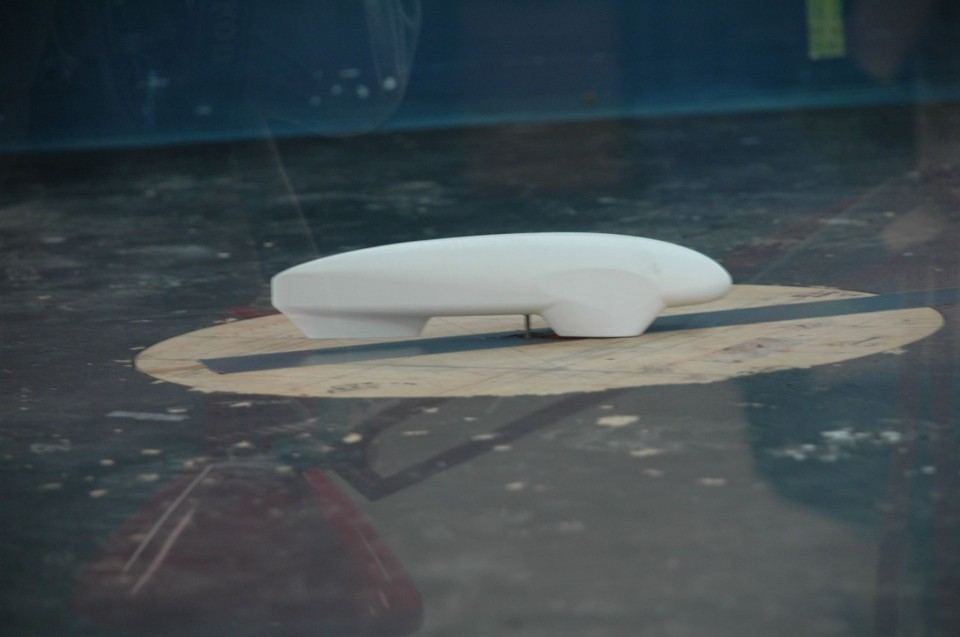

Wind tunnel tests

Models in 1:10 scale of Nova and our new bodywork has been tested in a wind tunnel.

The test was performed in six different wind speeds between 5.4 m/s and 19.6 m/s. The results indicates a reduction in drag force by 20 percent in a comparison between Nova and the new bodywork.

As the wind speeds are lower relative to the model size, the results are not directly applicable to the full scale model. Though we expect an even greater improvement in the end. The computer simulations which were previously performed helped us achieve a good result.

The work on the plug proceeds and right now slices of the plug are glued together. Take a look in the slideshow below for some pictures of the tests and the progress.

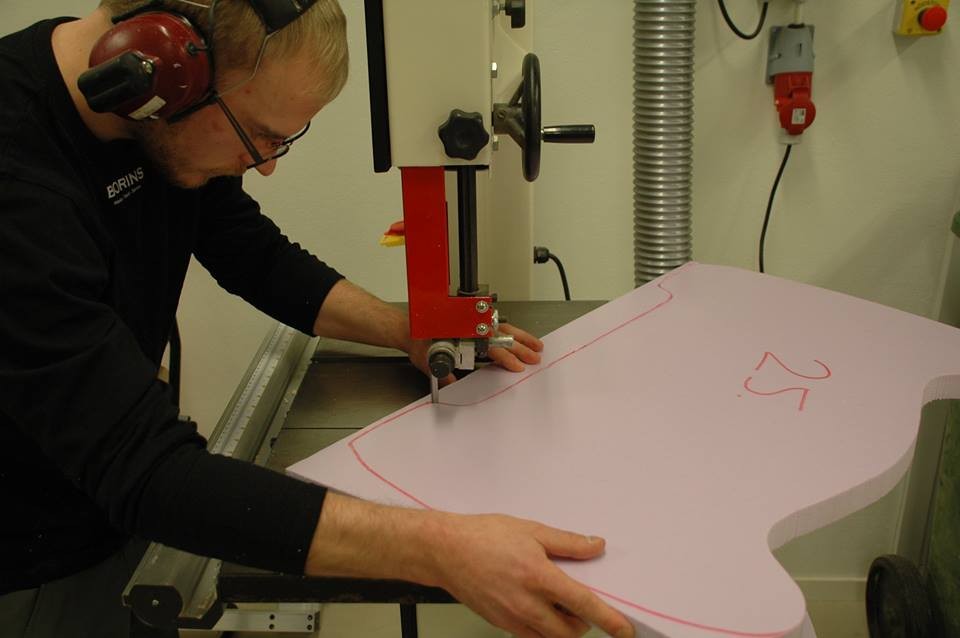

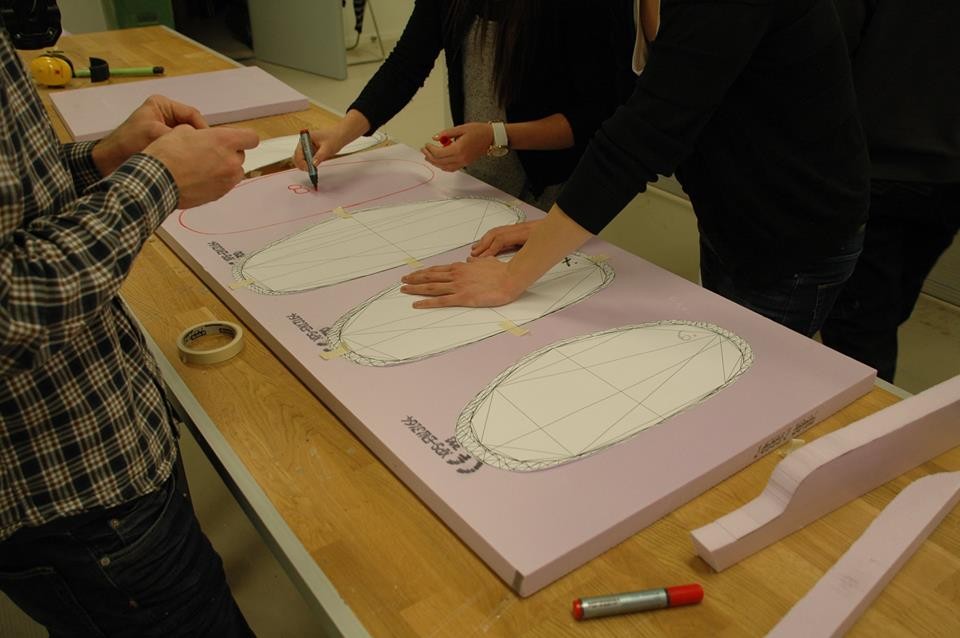

Bodywork workshop!

There are some action going on in the workshop! Further improvements according to aerodynamics will be achieved by a new bodywork. This year, team HiGtech will be manufacturing everything ourselves in the workshop. The slideshow below shows two 3D-printed models of what is the new bodywork and the old. The models will be tested in a real world wind tunnel to confirm our computerized simulations.

The work to produce a new plug is already running, which is also visible in the slideshow below. First, a large number of slices are cut, then the slices are glued together and sanded. After that the plug will be used to create a mold, in which the bodywork finally will be casted.

Simulations and optimizations

HiGtech are of course planning to attend at the Shell Eco Marathon 2015.

Currently we are looking at areas for improvement and have simulated several parts of Nova. Simulations will be used more frequently than before in our development activities this year.

The picture above shows an alternative to our present body. We run various prototypes in a simulated wind tunnel, which shows the magnitude of the drag force.

The engine with the surrounding parts are being optimized. The engine is soon to be connected to a test bench, in which it will be loaded and the fuel consumption will be measured.