There are some action going on in the workshop! Further improvements according to aerodynamics will be achieved by a new bodywork. This year, team HiGtech will be manufacturing everything ourselves in the workshop. The slideshow below shows two 3D-printed models of what is the new bodywork and the old. The models will be tested in a real world wind tunnel to confirm our computerized simulations.

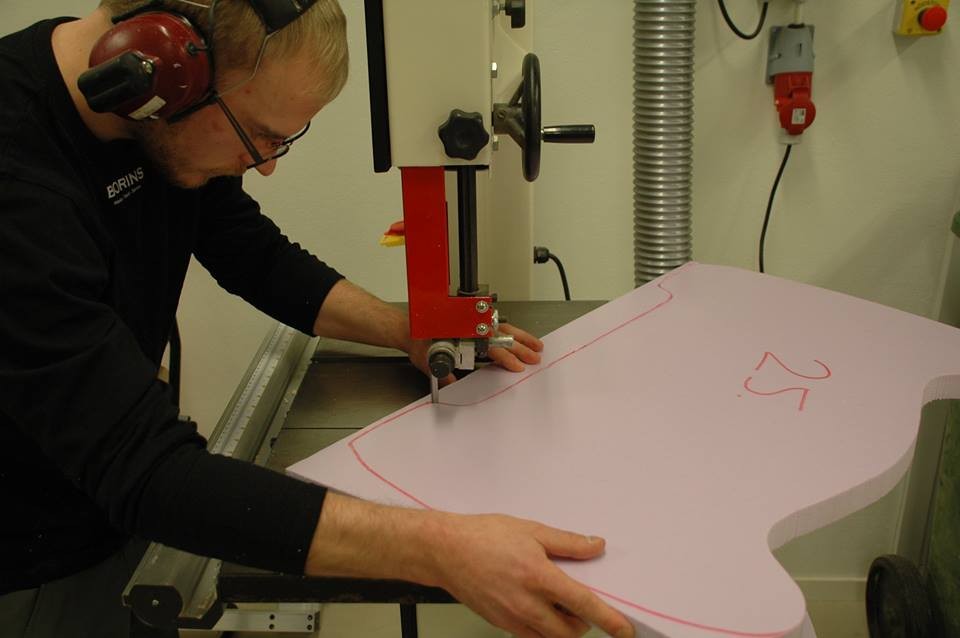

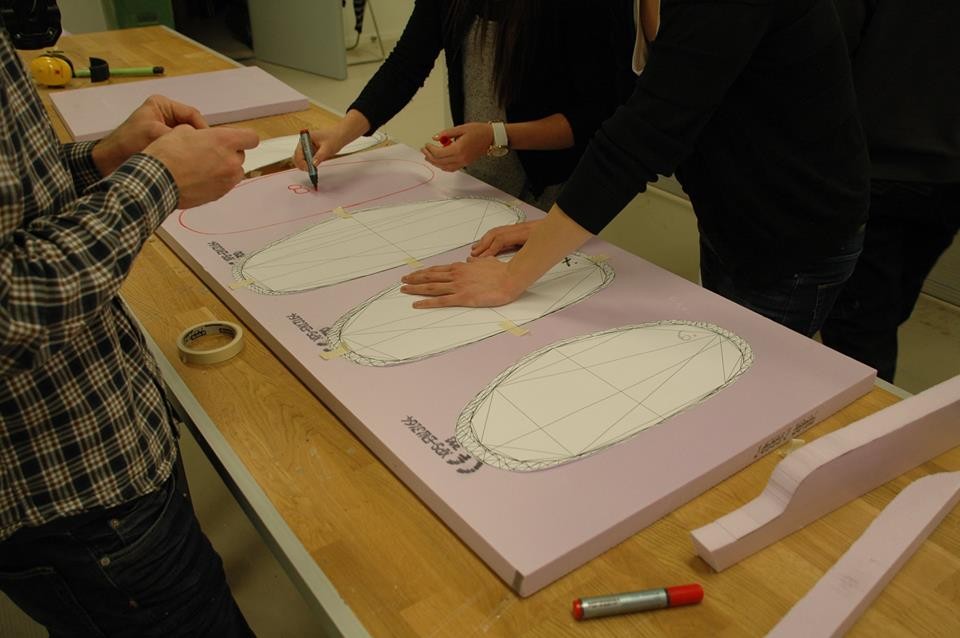

The work to produce a new plug is already running, which is also visible in the slideshow below. First, a large number of slices are cut, then the slices are glued together and sanded. After that the plug will be used to create a mold, in which the bodywork finally will be casted.