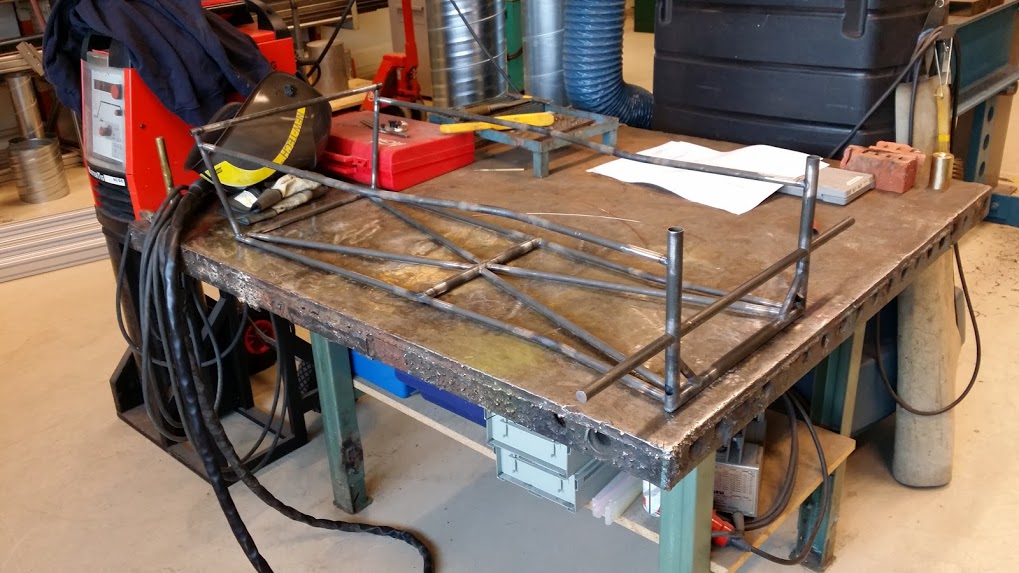

When arriving to the paddock today we had some problems with the ignition again, when the problems where solved we tried the car on the track, unfortunately we crashed the side of our car against the railing of the track. Luckily there was no physical damage to our driver, but we had to repair the body of the car.

We didn’t get everything ready for the race, but we have tested the car on a small test track. Now we are aiming to race tomorrow at 12:30.