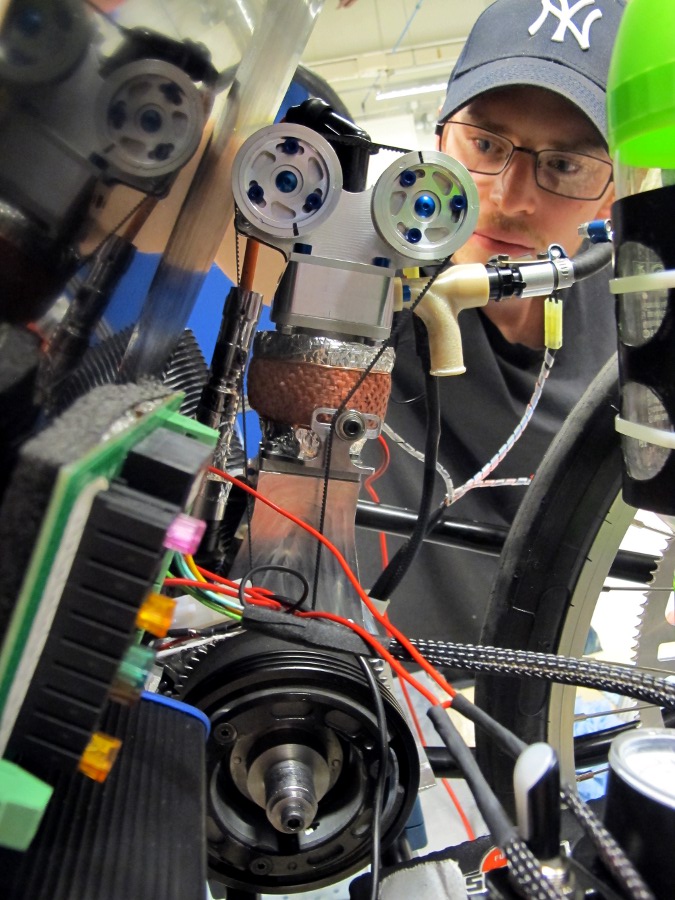

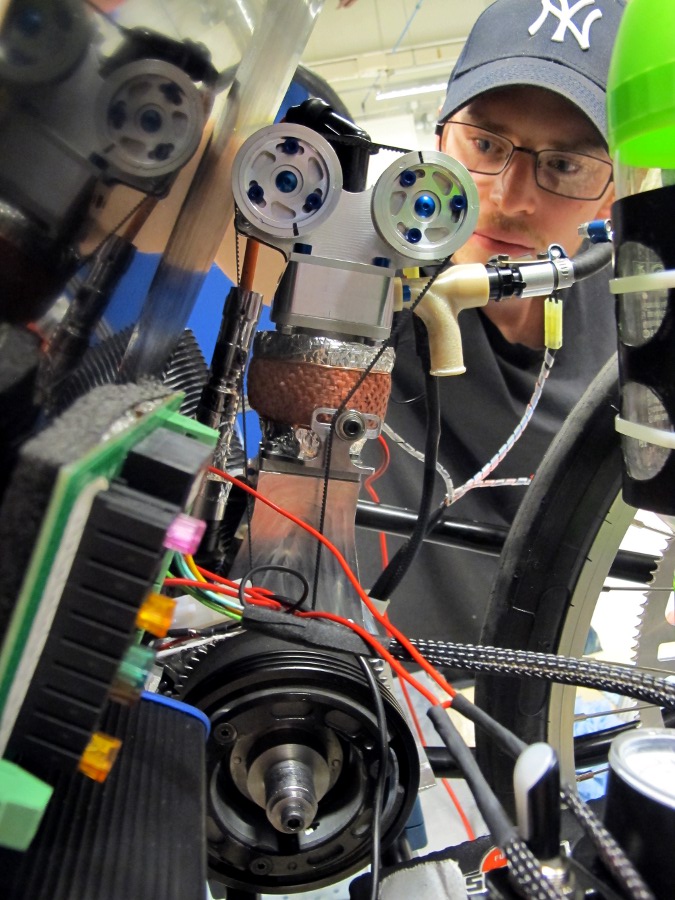

The engine is now mounted into the car and successfully started. The exhaust system is all that remains before the engine and drivetrain is ready for the race!

The engine is now mounted into the car and successfully started. The exhaust system is all that remains before the engine and drivetrain is ready for the race!

The engine HiG-145 is almost completed and will soon be mounted in the car.

Please take a look at the pictures in the slideshow below!

Hello again!

It’s been a while. Manufacturing of the engine progresses, smaller parts have been produced like valves, rockers and cam bearing holder. It may not look like much – but it’s the small parts that matters!

It starts to look like something! The manufacturing of our engine continues. Yesterday the cylinder head was completed and today we received two cylinders from Alderholmens Mekaniska.

The engine will use one cylinder, but we will test two different cylinders to achieve optimal function.

Take a look at the photos below and get an idea of how the engine will look like!

It’s Sunday, but the machines in the workshop are still running. We have been working all week to manufacture the engine and have managed to complete the crankcase, fasteners for camshafts and a few smaller parts. Please take a look at the photos below!

Hello!

During the week the manufacturing process started. Parts of the engine is still under development, but we’re approaching the set design.

The picture shows a cylinder that was machined in a CNC lathe in our workshop. The cylinder, which is made of aluminum, will now be coated and then the flanges will be milled to final shape.